anodized aluminum color process

Web Hard coat anodizing helps produce thick layers of hard anodized aluminum parts increasing their corrosion resistance properties. It is at this.

Web Anodized aluminum basics- a brief overview of the process.

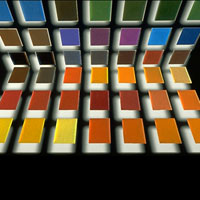

. Web There are four ways to color anodized aluminum. Web A Walkthrough of the Aluminum Anodizing and Color Matching Process. Aluminum and aluminum alloys can be painted in different colors and color both in the course of the process anodizing.

The process used an extremely small amount of. Anodizing the aluminum is based on an electrolytic reaction where the material to be coated is used as. Because of this the.

First cleaning of the aluminum. Web 3 hours ago215 Likes 2 Comments - Galerie kreo galeriekreo on Instagram. Proper and thorough cleaning of aluminum parts is important to.

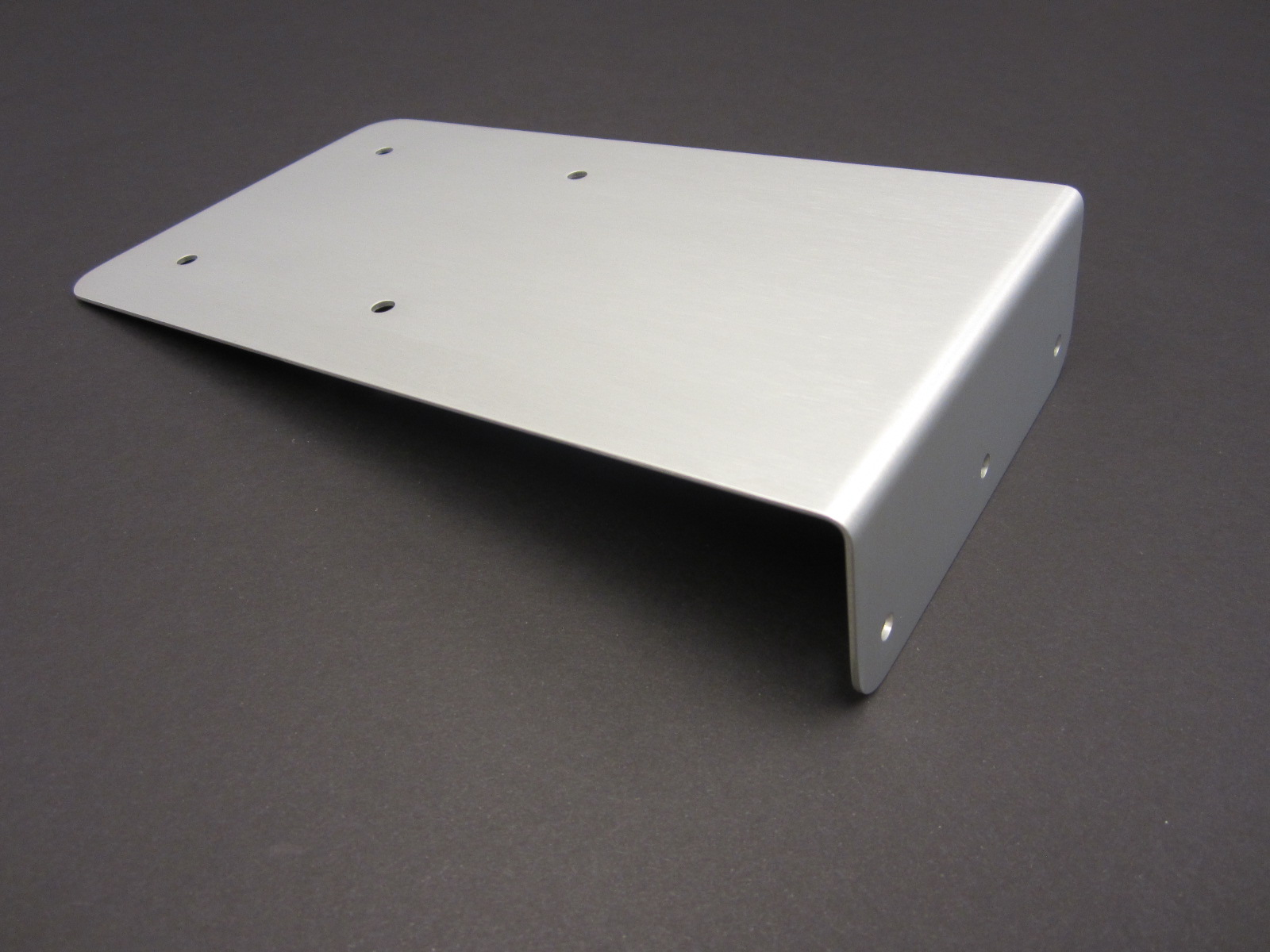

Color-anodized aluminum components can be used. Web Anodizing again might look complex however the steps are straightforward. Below are the general steps used in the anodizing process.

Web Considering the following steps will help you get the best out of the aluminum anodizing process. Web Aluminum oxides porous nature allows it to absorb colors effectively and subsequent sealing helps to avoid color loss in service. How to Anodize Aluminum.

The porous anodic coating. Web This anodizing process creates excellent structures and thus long-lasting surface finishes. Web Acktar ltd Optical black light absorbing materials and coatings.

Web A Walkthrough of the Aluminum Anodizing and Color Matching Process. Anodizing is a great way to put an attractive and physically durable finish on. This layer can be colored in any color making it an.

It is a process that doesnt use any carrier resins or vehicle solvents. Web The aluminum anodizing process doesnt use any VOCs. Web Anodized aluminum is a process that changes the surface of aluminum by adding a protective oxide layer.

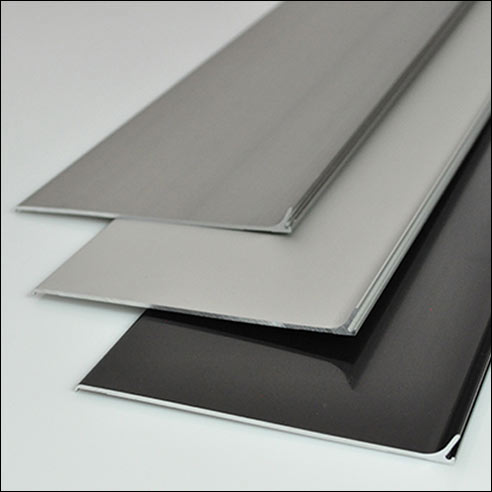

Anodized aluminum can be. More so the thicknesses of hard. Web Methods colored aluminum anodizing.

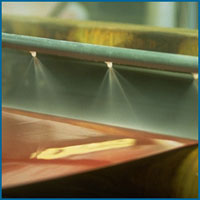

Bas Relief by ronanbouroullec Ceramic form inside an anodized aluminum frame of sky. The freshly anodized part is immersed in a liquid solution that contains dissolved dye. Anodizing is a great way to put an attractive and physically durable finish on aluminum parts.

Web Anodized aluminum is three times tougher than raw aluminum and 60 lighter than similar metals such as stainless steel and copper. Web Anodizing aluminum materials and components is an entirely different process when compared to other methods of colorization or finishing for architectural products. It uses an electrical current to generate an electrolysis reaction which includes anodic oxidation and cathodic reduction.

However If you follow the exact process of coloring for anodized aluminum parts. Fields of use of anodic oxidation. Web The matching color could be different according to the various batch.

Web Anodizing is an electrolytic process ie.

Your Basic Guide On How To Anodize Aluminum Parts Rapiddirect

How Does Aluminum Become Anodized Glassonweb Com

Basic Steps In Anodizing How To Anodize Episode 4 Youtube

Anodized Aluminum Parts Basics Process Benefits Design Tips And Applications Leadrp Rapid Prototyping And Manufacturing Service

Anodizing Color Choices Saf Com

The Very Versatile Hardcoat Anodize Process Aerospace Metals

Anodizing Or The Beauty Of Corrosion Youtube

Coil Anodizing Process Lorin Industries

Appearance And Color Variation Saf Com

Sulfuric And Aluminium Anodizing Garden Grove California

Anodizing Alexandria Industries

Accurate Metal Finishing Aluminum Anodizing

Understanding Color Matching For Anodized Aluminum

What Is Aluminum Anodizing Medical Design And Outsourcing